Kev sib xyaw yog muab faib ua kev sib xyaw ua ke thiab kev sib xyaw ua ke.Tam sim no, cov khoom siv dag zog los yog mortar mixers yog siv rau hauv kev lag luam los sib xyaw cov ntaub ntawv, thiab kev sib xyaw ntawm phau ntawv tsis siv Cov Khoom Siv thiab cov cuab yeej: cov khoom siv dag zog los yog cov khib nyiab, cov thoob, nplai, vibrators, cuab yeej shovels, trolleys, thiab lwm yam.

Kev siv dej hauv kev tsim kho yog ua raws li cov dej siv tau teev tseg hauv daim ntawv tshuaj ntsuam xyuas zoo ntawm cov khoom lag luam, thiab nruj me ntsis ua raws li cov qauv kom ua tiav qhov ntsuas qhov tseeb.

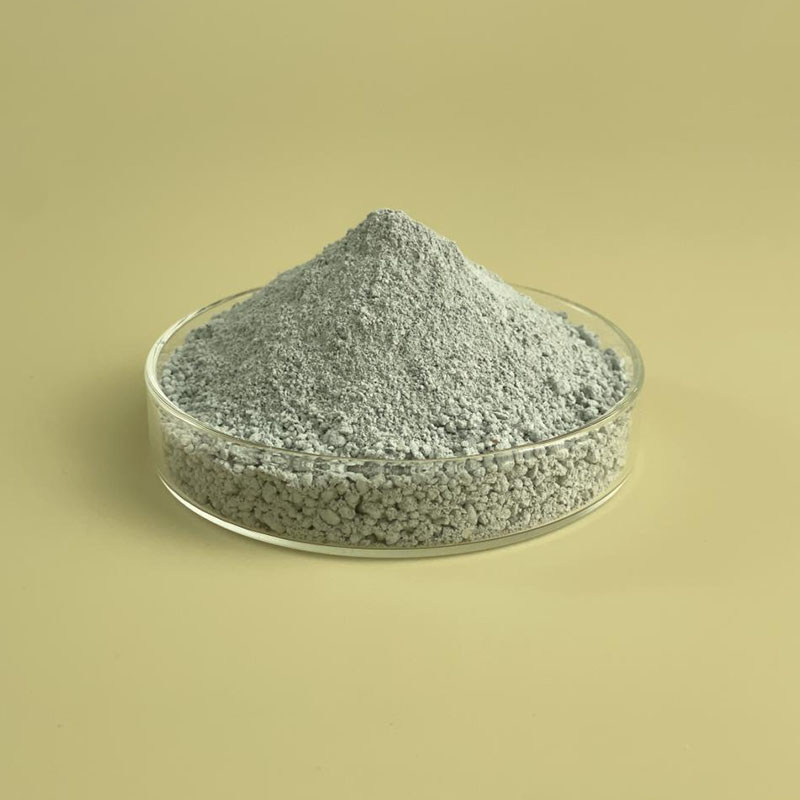

Mixing: Sib tov qhuav ua ntej thiab ces ntub.Muab cov khoom ntim rau hauv lub tov khoom thiab qhuav rau 1-3 feeb nyob rau hauv qhov kev txiav txim ntawm lub hnab loj ua ntej thiab ces lub hnab me me kom nws sib npaug.Qhov hnyav ntawm txhua qhov sib xyaw yog txiav txim siab raws li cov tshuab thiab kev tsim kho ntim;Raws li qhov hnyav ntawm cov khoom siv, cov dej xav tau rau txhua qhov sib xyaw yog ntsuas kom raug raws li cov dej tau teev tseg, ntxiv rau cov khoom sib xyaw ua ke qhuav, thiab tag nrho stirred.Lub sij hawm tsis pub tsawg tshaj 3min, kom nws muaj qhov haum fluidity, thiab tom qab ntawd cov khoom tuaj yeem tso tawm rau kev nchuav.